|

|

|

|

|

|

TABLE of CONTENTS

|

Recycled asphalt pavement use is increasing |

By Sue Roe

This is a road reclaimer used to do full depth reclamation. The reclaimer is often called a rototiller for pavements because it grinds up the asphalt pavement and existing base layer together. The “teeth” of the reclaimer can be seen underneath in the middle. Photo by Tim Andersen |

MnDOT has long been a leader in the use of recycled asphalt pavement or RAP. Much of the nation’s current use of RAP in hot mix paving asphalt is based on the methods first used in a 1978 project that reconstructed the streets in what is now the 3M campus in Maplewood.

Subsequent MnDOT projects using as much as 80 percent RAP in hot mix paving revealed significant pavement performance problems, according to Curt Turgeon, state pavement engineer.

Currently, MnDOT asphalt paving specifications allow 30 percent RAP in overlay projects and 20 percent RAP when crack resistance asphalt cements are used in new or reclaimed pavements.

For economic and environmental reasons, Turgeon said MnDOT has renewed interest in increasing the use of RAP. Work includes trials of varying percentages in hot mix, trials at MnROAD of cold central plant recycling, and continued use of cold in-place recycling and full depth reclamation.

Increase in hot mix percentages

In District 6, a 13-mile section of the 30-mile Hwy 52 resurfacing project contains 40 percent RAP on the wide outside shoulders. The mixture contains proprietary additives to potentially assist in the rejuvenation of the RAP.

Tom Meath, District 6 materials engineer, said the higher percentage is being used because of the abundance of RAP available.

“This project allows the contractor to use up stockpiles of pavement from this and other projects and reduces the amount of new material needed, while not diminishing the quality of what’s used in the traveling lanes,” he said.

Meath said there are counties and cities in District 6 already using 40 percent RAP, but this is the first time MnDOT is trying it.

“We’re trying to figure out ways to use more RAP,” he said. “That’s a lot of money sitting there when we remove an asphalt pavement.”

Cold central plant recycling

This year’s MnROAD reconstruction, funded by the National Road Research Alliance, contains test sections of cold central plant recycling. This process uses 100 percent RAP mixed in a standard plant at ambient temperatures using an emulsified or foamed asphalt cement. The result is a product that is not resilient enough be used as a top surfacing so the test sections will receive either a standard hot mix overlay or a double chip seal.

Cold in-place recycling

The resurfacing portion of the Hwy 110 project east of I-35E and I-494 in Mendota Heights and Inver Grove Heights will use 100 percent recycled asphalt as the base layer of pavement.

Tim Clyne, Metro pavement and materials engineer, said using 100 percent saves on rock and asphalt costs, trucking costs and time. Since the material is reused with the cold in-place recycling process, the result is a more variable product than the material produced at the plant. Hot mix will be used as the top surface.

“It’s not a new technology, but this is the first time Metro has used the 100 percent RAP in at least 30 years,” he said. “It provides a long-term pavement solution for an extended pavement life.”

See a video of cold in-place recycling, which shows a milling machine, a machine that screens and crushes oversize materials and then mixes in an asphalt emulsion, an asphalt tank and an asphalt paver and roller.

Full depth reclamation

Full depth reclamation uses equipment often described as a rototiller for pavements. The asphalt pavement and some of the existing base is ground together in place. Multiple passes of the reclaimer are often used. The final pass may include the addition of a binder such as asphalt emulsion, foamed asphalt, cement or lime. The result is an aggregate base with the old crack pattern completely erased.

“Hot mix overlays on full depth reclamation base have shown excellent performance compared to a typical mill and overlay project,” said Turgeon.

Economic and performance benefits of these techniques are well understood. Until recently, the environmental benefits of using materials in place instead of hauling off to a plant haven’t been well documented. MnDOT participates in the Recycled Materials Resource Center pooled fund project now housed at the University of Wisconsin – Madison.

In June 2017, the RMRC completed an analysis of nine paving projects that documented an average of 22 percent overall savings and 20 percent savings in water usage. |

|

|

|

|

TABLE of CONTENTS

|

MnDOT presence will show State Fair goers depth of the agency |

|

By Dana Hernandez It’s time for another round at the Minnesota State Fair, where MnDOT employees will have a presence each day from Aug. 24 – Labor Day, Sept. 4.

If you’re making it to the fair, here’s a guide of all things MnDOT you won’t want to miss:

The MnDOT State Fair booth includes hands-on bridge parts/materials and features the new St. Croix Crossing. Photo by Kevin Gutknecht |

Education Building

Like previous years, the booth is located in the Education Building at 1372 Cosgrove St.

The 2017 display showcases how MnDOT uses innovation and technology to be more efficient, and also:

- Features key technology improvements that help manage traffic congestion around work zones

- Includes hands-on bridge parts/materials and photo opportunities

- Promotes 511mn.org

Employees will be engaging the public, answering questions and handing out state highway maps to fair goers.

Eco Experience Building

MnDOT is participating in the Kick Gas exhibit located in the Eco Experience Building at the corner of Cosgrove Street and Randall Avenue.

At this exhibit, the public will:

- Learn about vehicle pollution, ways to reduce vehicle use and improve mileage

- Learn safe walking behaviors in “Safety Town”

- Help power the “giant bike”

- Increase knowledge of transit, car and bike sharing

Employees will be handing out state bike maps to fair goers.

State Fair Parade

The parade begins at 2 p.m. daily. There will be three opportunities to see a MnDOT snowplow, the public engagement GoMobile and fellow employees participating:

- Tuesday, Aug. 29

- Wednesday, Aug. 30

- Thursday, Aug. 31

Dan Patch Park

Thursday, Aug. 24, is STEM Day at the fair in Dan Patch Park. Volunteers with MnDOT’s STEM Education and Outreach program will engage children, grades K-12, in science, technology, engineering and math.

Come support your coworkers and stop by a MnDOT exhibit during the 12-day run at the State Fair.

For more information, check out the MnDOT State Fair website.

Part of the 2017 MnDOT State Fair display features work zone safety. Graphics created by Adam Oie |

|

|

|

|

|

TABLE of CONTENTS

|

I-35W 'smart bridge' test site uses vibration data to detect bridge defects |

By MnDOT Research Services & Library staff

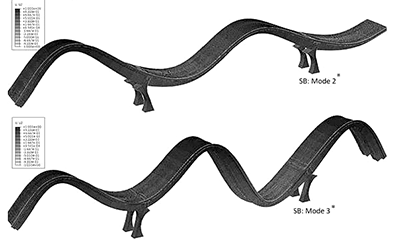

By analyzing the frequency and shapes of vibration waves, researchers established a fingerprint of the different ways in which the I-35W St. Anthony Falls Bridge naturally vibrates due to traffic and environmental factors. |

An electronic monitoring system on the new Interstate 35W St. Anthony Falls bridge uses vibrations to help monitor the bridge’s structural integrity. By analyzing the vibration data, MnDOT is working to develop monitoring systems that could detect early structural defects and ultimately allow engineers to improve bridge designs.

A research study was completed in February.

“The study gets MnDOT closer to using bridge monitoring systems in combination with visual inspection to help detect structural problems before they affect safety or require expensive repairs,” said Benjamin Jilk, Bridge Office, the project’s technical lead.

In September 2008, the I-35W St. Anthony Falls bridge was constructed with the “smart bridge” electronic monitoring system. More than 500 sensors continuously provide data on how the concrete structure bends and deforms in response to traffic loads, wind and temperature changes. Transportation agencies are increasingly interested in such systems. As a complement to regular inspections, they can help detect problems early on, before the problems require expensive repairs or lead to catastrophic failure. Smart bridge systems can also help engineers improve future bridge designs.

Completed in 2008, the I-35W St. Anthony Falls Bridge has a smart bridge monitoring system that includes hundreds of sensors. File photo |

The smart bridge system has accelerometers, which provide data on the way the bridge vibrates in response to various stimuli, including structural damage. Vibration-based monitoring has the advantage of allowing damage to be detected at any location within the bridge rather than only at the specific locations where measuring devices have been placed.

However, it can be difficult to use vibration monitoring to detect damage when vibration is masked by the bridge’s natural response to traffic loads, wind, temperature changes and other environmental conditions. A crack in a bridge girder, for example, can produce a vibration signature similar to one produced by a change in beam length due to variations in temperature or other causes. Consequently, since 2008 MnDOT has conducted a series of research projects using data from the St. Anthony Falls Bridge to establish a way to distinguish anomalous data indicating a structural defect or damage from background “noise” associated with other causes.

The monitoring system has confirmed the bridge is behaving as designed.

MnDOT continues to collect data from the bridge as it ages to further understand its behavior. This will provide an opportunity to determine how anomalies in vibration data correspond to cracking and other forms of structural distress. Ultimately, MnDOT hopes to use this bridge monitoring system in combination with visual inspection, both to detect problems in bridges earlier and to develop better bridge designs.

A follow-up research study will determine the effects of temperature on the bridge’s dynamic and long-term vertical displacements, which can be used to monitor the bridge’s stiffness, connections and foundations.

|

This video describes a method of analyzing accelerometer data from the I-35W St. Anthony Falls Bridge to establish how the bridge naturally vibrates in response to traffic, wind and other environmental conditions. With this fingerprint of the bridge's vibration, engineers have a baseline against which to measure anomalies in bridge monitoring data that might indicate structural damage. Video created by University of Minnesota's Center for Transportation Studies |

|

|

|

|

|

TABLE of CONTENTS

|

STEM program introduces students to transportation careers |

|

By Dana Hernandez

Scott Theisen, Bridge Office, demonstrates a snooper to students during a STEM tour May 6. Photo by Nicole Bartelt |

Experts predict significant growth in the demand for qualified employees in science, technology, engineering and math fields. Aware of this, MnDOT developed the STEM education and outreach program for children, grades K-12 - Minnesota’s future generations of civil engineers and technicians.

The Bridge Up! curriculum, designed by MnDOT, teachers and other external partners, is an interactive learning program that brings students closer to the every day work of engineers and construction workers.

The curriculum provides teachers with resources that require little-to-no training in order to educate students. It includes three main components for different grade levels: an iBook (K-3), web modules (4-8) and lesson plans (K-12).

“Bridge UP! is really a gateway to STEM. We are reaching out to younger generations for a sort of early recruitment and retention,” said Nicole Bartelt, hydraulic design engineer and STEM education and outreach coordinator. “We also want to reach students from different communities. By working on the diversity aspect of our outreach efforts, we can reflect what the state of Minnesota looks like within MnDOT to better serve our community’s needs.”

Part of Bartelt’s work with STEM outreach is to make the program more known throughout MnDOT. Schools often request transportation professionals to attend events and activities, and because of this, she is always looking for MnDOT employees to volunteer in the program.

Tom Styrbicki, Project Management and Technical Support director and state design engineer (seated at table in white shirt), speaks to students during a STEM presentation in March. Photo by Nicole Bartelt |

“Volunteers are on MnDOT time, within reason. They can give presentations, participate in activities or become mentors, depending on grade level,” said Bartelt.

Volunteers show students the possibilities that careers in transportation have to offer.

“We also like to encourage MnDOT employees to share these resources, such as the Bridge UP! curriculum, with their children’s school districts and after school programs,” said Bartelt.

The outreach program is again participating in STEM Day at the Minnesota State Fair on Thursday, Aug. 24. Volunteers will be located at Dan Patch Park from 8 a.m. to 5 p.m.

To become a volunteer, learn more or be added to the distribution list, contact Nicole Bartelt at the stem outreach inbox or any of the district STEM outreach representatives in your area.

Further resources can be found on the external STEM site. |

|

|

|

|

TABLE of CONTENTS

|

High school students participate in National Summer Transportation Institute camp |

By Adrienne Bond, Office of Civil Rights

Goldy the Gopher and NSTI staff members Abeer Syedah (left) and Talia McLeish (right) look on as MnDOT engineer Julie Johnson monitors the bridge built by students as sand is added to test the bridge’s strength. Photo by David Gonzalez |

Where do you find University of Minnesota mascot, Goldy the Gopher, MnDOT staff, and 31 high school students excited about highway construction? The answer is the National Summer Transportation Institute.

On July 28, 31 students in grades 9-12 completed the National Summer Transportation Institute camp hosted by the University of Minnesota. The two-week summer camp was hosted by the Center for Transportation Studies, with funding from Federal Highway Administration and administered by MnDOT’s Office of Civil Rights.

The NSTI Program is a transportation-focused career awareness initiative, designed to introduce high school students to all modes of transportation-related careers. Participating students are exposed to a variety of transportation activities and career pathways over the course of the camp; they spend time at the University of Minnesota campus, out in the field meeting people in the industry, and working on group projects.

Some of the activities included:

- Learning how signs are made at the Hennepin County Maintenance Facility sign shop

- Designing and naming virtual roads, with the help of MnDOT transportation planners

- Touring a construction site

- Operating driving simulators to learn traffic safety

- Exploring the St. Paul airport as an introduction to aeronautics

The camp concluded with a graduation ceremony where the students gave construction, design and load testing presentations on bridges built from hot glue and popsicle sticks. Student groups developed blueprints, got plan approval from MnDOT bridge engineers and worked in bridge-building teams.

Each team had a budget of $300 and “spent” $50 per bundle of 50 popsicle sticks and $10 per hot glue stick. For load testing, a bucket suspended below the bridge, was filled with sand until bridge buckling occurred. The bucket was weighed to determine the amount of weight before it would buckle. Students were given overall ratings based on:

- Weight of bridge

- Cost of supplies

- Weight bridge could support

While one bridge held an amazing 68 pounds, the winning bridge was the lightest and strongest as it held 25 pounds of sand. It was also the cheapest, as it used just over one-third of the budgeted amount of building materials (glue and popsicle sticks).

Brandon Day and Julie Johnson, MnDOT bridge engineers, assisted the students with bridge design, monitored the load testing and determined when the bridges were no longer structurally sound. The experience was rewarding for Day and Johnson.

“It is fun to work with smart kids that want to be here,” said Day. “When I explain physical phenomenons to them and see the understanding click in their head, the smile that comes with it reminds me of what brought me to engineering.”

Goldy the Gopher also made an appearance, entertaining spectators and taking photos with the students.

The enthusiasm and energy brought to the program by the students was inspiring to Johnson.

“It is so important to get young people exposed to and interested in science and engineering,” she said. “It was rewarding to work with the kids and see them excited about transportation.” |

|

|

|

|

TABLE of CONTENTS

|

Janet Cherney named assistant division director for Corporate Services Division |

Janet Cherney is now working at CO in the Corporate Services Division Photo by Stephen Terhaar |

Janet Cherney was appointed July 12 to a temporary position as assistant division director for the Corporate Services Division.

Cherney has served as the director of Business and Administrative Services in the Metro District since October 2013. She has also served at the Department of Public Safety and Minnesota Management and Budget, primarily in accounting roles. In 2006, she was hired as the accounting director for DNR, Division of Forestry, and became a manager with a focus in accounting, human resources and facilities.

Cherney reports to Sue Stein, assistant commissioner for the Corporate Services Division. She has experience in the areas of change management, continuous improvement, business planning, talent management, annual spending plan development, financial reporting and analysis, records management and strategic planning, which she will bring to the Corporate Services Division.

“I am excited to have Janet take on this new role with the agency,” said Stein. “She has a broad array of experience and knowledge that will serve us well.”

Cherney, who has a Bachelor of Science degree in accounting with a minor in promotional communications, has 22 years of state service. |

|

|

|

|

TABLE of CONTENTS

|

Spatial Data Warehouse now includes data with land referencing system measures |

By Peter Morey, Data Systems & Coordination

Research analysts, planners and others who use GIS data take note: The project to update MnDOT’s Spatial Data Warehouse to include data from the new Linear Referencing System has completed another phase. It now includes data with LRS measures.

SDW is a collection of spatial data that includes a location aspect so that it can be put on a map. MnDOT’s SDW contains data that the agency has created, is commonly used, and requires minimal security.

Data is now available for users who want to plot their own data against the LRS routes. In order to plot data against the measured LRS data, it must be updated to include measures associated with the LRS routes. Legacy Transportation Information System measures should not be mixed with measures that come out of the new LRS.

For more information, see the LRS web page. (A list of non-measured data can also be found here.) For step-by-step instructions on how to connect to the new SDW, see the How to transition to 11G Spatial Data Warehouse document.

Contact Peter.morey@state.mn.us with questions. |

|

|

|

|

TABLE of CONTENTS

|

On-the-Job: Dave Cowan helps provide safe routes to schools |

By Sue Roe

Do you or a co-worker have an interesting job to share with readers? Send us your ideas, and we’ll contact you for more information.

Recent employee profiles:

|

|

|

|

|

|

|

TABLE of CONTENTS

|

WIG 2.0 Report Out shares accomplishments, lessons learned |

By Tracy Hatch, deputy commissioner, chief operation officer and chief financial officer

Tracy Hatch, deputy commissioner, chief operation officer and chief financial officer. Photo by Rich Kemp |

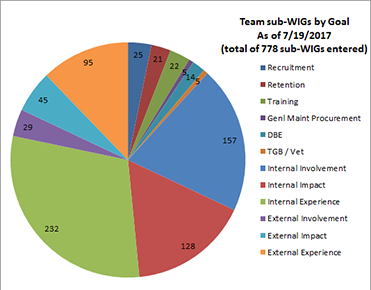

As we approach an important milestone, about midway into WIG 2.0, I’d like to share with you some of the successes we’ve had along the way and ask for your continued support and dedication. Employees from all over the agency are working on more than 800 sub-WIGs, at various stages, dedicated to help move the needles to advancing equity and improving intentional customer engagement.

On Aug. 3, MnDOT managers, champions, 4DX coaches and other agency leaders met virtually for a quarterly report out to provide the opportunity for agency leaders to present to MnDOT Senior Leadership and champions their progress with WIG 2.0.

A variety of topics were covered during the meeting that included major accomplishments, lessons learned, where teams might be having problems, idea and information sharing, and updates on the next steps.

Managers, champions, 4DX coaches, and other agency leaders presented their progress with WIG 2.0 during a meeting Aug.3. |

The quarterly reportouts are important for our cadence of accountability. It includes leaders evaluating what the teams reporting to them are doing and how closely they are working within the framework of the 4 Disciplines of Execution (4DX). So far, we’ve focused on “progress not perfection.” As the agency and teams grow in their practice of 4DX, we’ll begin to look more closely at the quality and application of 4DX. We also took the time to review team scoreboards. I am so excited about the effort and creativity that goes into them. Many are so innovative, imaginative, inspiring—and some show such great humor! I love that. I encourage you to check them out. You can find them at scoreboard slideshow.

Recently 12 teams were recognized for their WIG 2.0 efforts in Shout Out! – Round 1. I want to add my personal thanks to the winning teams for your efforts to help move the needle. It’s very exciting to see so much positive energy being devoted to WIG 2.0. A highlights video was created to showcase each of the winning teams’ accomplishments. You can view that at Shout-Out Video showcase. I know there are a lot of amazing people devoted to WIG 2.0 across the state – watch for more “shout-out” opportunities coming soon.

I think Betsy Parker, chief counsel and co-champion for Advancing Equity said it best at the report out when she said, “It feels like things are changing. Every time there is a step forward we realize - ‘Yes! I can do this!’"

My heartfelt thanks to everyone for all your hard work and I ask you to continue to make weekly commitments, explore the many resources available on the WIG 2.0 SharePoint and iHub site and look at what other teams are doing for their sub-WIGs to get ideas. If you have questions, please don’t hesitate to ask any member of Senior Leadership team, WIG champions, and WIG coaches or send an email to MN_DOT_WIG. We’re here to help!

I want to remind you that even if it seems like your efforts might not be making a difference, remember there are 5,000 MnDOT employees across the state who are all working towards moving the needle by each making one WIG commitment per week. There’s such power in that - it means 260,000 actions per year to help MnDOT Earn Customer Trust!

Thank you, once again, for everything you do, every day for Minnesota. |

|

|

| |

|