|

|

|

|

TABLE of CONTENTS

|

FIRST driver Mike Howe rescues runaway dog |

By Kristi Loobeek

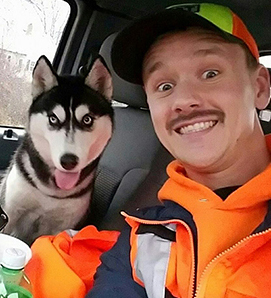

Mike Howe, FIRST driver, rescued a Siberian Husky Nov. 28 on Hwy 36 in Little Canada. Photo by Mike Howe |

“It’s not the same old ‘sitting at a desk every day.’ It’s always different.”

Mike Howe’s description of his job on the Freeway Incident Response Safety Team was especially true Nov. 28 when he rescued a runaway Siberian Husky from the side of Hwy 36 in Little Canada.

Howe, a FIRST truck driver, has been assisting motorists (and the occasional canine) in the Twin Cities for more than three years.

The rescue began with a stopped vehicle on the side of the road. A passing driver had spotted the handsome hound and pulled over to attempt to corral him.

Howe said that, normally, a lost dog will run for miles and when captured, they are anything but friendly.

That was not the case with Parker, the two-year-old Siberian Husky.

“I opened the truck door and said, ‘Wanna come in?’ and he hopped right up,” said Howe, noting that Parker was calm and friendly during the whole incident.

Parker, who had a microchip, was reunited with his owner Nov. 29. Photo by Mike Howe |

Once the dog was out of harm’s way, the search for the owner began. Howe took a few photos of Parker and passed them along to his supervisor.

Eventually, the photo landed on the MnDOT Facebook page, explaining the situation and asking anyone who recognized the animal to alert its owner.

The dog’s information and owner were later identified through a scanned microchip at Hillcrest Animal Hospital. In the meantime, multiple people on Facebook offered to adopt the dog if no owner was located; thankfully, that was not needed. Parker and his overjoyed owner were reunited the next day.

After posting the story and photo on the MnDOT Facebook page, the post reached 52,962 people, received 757 likes and had 422 shares.

|

|

|

|

|

TABLE of CONTENTS

|

New features on 511 traveler information system will help public make good driving decisions |

By Sue Roe

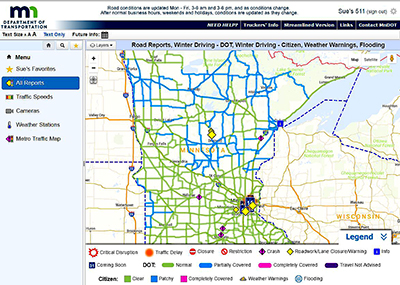

The 511 winter traveler information system has new features to help motorists know what the state’s road conditions are like before they travel. The features include citizen reporting, personalizing routes and new icons such as a red triangle over a weather station icon when fog, high winds and winter conditions exist. |

Motorists using MnDOT’s 511 traveler information system this winter have several new features to help them know what the state’s road conditions are before they venture out on the roadways.

“Overall, the 511 traveler information system is getting better each year and more people are using it,” said Kelly Braunig, 511 program manager. “These new features will help the traveling public make good decisions about winter travel.”

She said one million more motorists used the mobile app in 2015-16 than in the previous winter season. There were also significant increases in the number of users on the truckers’ and full-featured web pages.

Some of the new features this winter are:

- Personalize Your 511 – Motorists can enter up to 20 routes they travel to see where incidents, such as crashes or construction, are located. Users can also click on a specific incident to see a camera view. This is available on the full-featured and truckers’ pages.

- Smart 511 – This is the same as Personalize Your 511, but for a smartphone. Motorists sign up online and then enter their phone number to receive information.

- Citizen Reporting – Motorists can submit driving conditions to the 511 system along a saved route. To use this function, users must have an account through the “Personalize Your 511” feature. Users take a short online course to get registered. Motorists are advised to report driving conditions after they reach their destination. This is available on the full- featured site, but soon will also be on the truckers’ site.

- Tell Me – Motorists receive hands-free and eyes-free audio notifications on their smartphones about traffic conditions. Users download and open the app before they start driving. The feature uses motorists’ GPS information.

- Traffic Delay – On the traffic map, there is now an orange glow around an icon when there is a traffic delay due to a crash, construction or other traffic-slowing incidents. When users click on the orange glow, information will be provided on delays, travel times and direction of the delay. This is currently available only for interstate driving and shows a delay within two miles in each direction of an incident. This feature is on the truckers’ and full-featured sites.

- Road Weather Information System Alert – On the full-featured and truckers’ sites, motorists will see a red triangle over a weather station icon when weather conditions such as fog, high winds, rain, ice and snow exist.

Most of the features are beneficial for winter driving, but they can also be used year-round.

Braunig encouraged MnDOT employees to go to www.511mn.org to check out how the site and features work and use it this winter. The mobile device app is free to download. |

|

|

|

|

TABLE of CONTENTS

|

FHWA designates Interstate 94 corridor as an alternative fuel route |

|

By Judy Jacobs

Commissioner Charlie Zelle drives one of MnDOT’s electric vehicles. Photo by David Gonzalez |

Interstate 94 from Detroit, Mich., to the Minnesota/North Dakota border is one of 55 routes the Federal Highway Administration has designated nationally to promote alternative fuels and help drivers find vehicle charging stations nationwide.

This new network spans 35 states, covers 85,000 miles and was created under the Fixing America’s Surface Transportation Act. The alternative fuel corridors designation will be used to promote electric, hydrogen, propane and natural gas vehicles by encouraging development of fueling and charging stations along these routes.

“Alternative fuels and electric vehicles will play an integral part in the future of Minnesota’s transportation,” said Commissioner Charlie Zelle. “MnDOT is excited to be a part of helping drivers identify routes that will help them refuel and recharge those vehicles. Designating the I-94 Corridor is a great place to start the process.”

MnDOT and the Minnesota Pollution Control Agency submitted an application to designate I-94 as a ‘Zero Emissions Corridor,’ a type of alternative fuel corridor, to promote electric vehicle charging infrastructure.

“Interstate 94 from Minneapolis to St. Cloud has been designated as ‘signage-ready’,” said Tim Sexton, Office of Environmental Stewardship’s Construction and Operations Section director. “The designation means there is an existing network of public fast-charging stations close enough to one another for motorists to reliably travel the corridor with today’s models of electric vehicles. FHWA is developing final guidance on sign design and placement, but they’re expected to look similar to existing signage that alert drivers to gas stations, food and lodging.”

“By supporting lower emission vehicles, alternative fuel corridors will help reduce transportation emissions, the leading source of U.S. greenhouse gas emissions,” Sexton said.

“Identifying where alternative fueling stations can be found will help the public in many ways,” Zelle said. “We can accelerate the use of innovative vehicles, improve air quality and ensure that our transportation system meets the needs of the 21st century drivers.”

For a complete list of alternative fuel corridors, visit the FHWA website. |

|

|

|

|

TABLE of CONTENTS

|

Maintenance Decision Support System helps MnDOT fight winter efficiently, effectively |

By Sue Roe

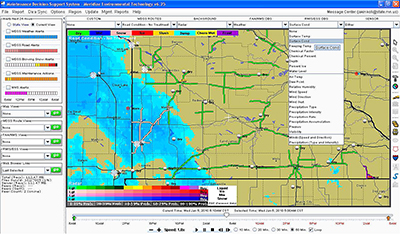

This is what the MDSS system looks like on a computer screen. The system integrates multiple sources of data and provides maintenance recommendations to snowplow operators, supervisors and managers. |

This winter, MnDOT is using its Maintenance Decision Support System, or MDSS, to full capacity and expectations are that it will bring the ability to fight snow and ice to a new level and with greater efficiencies.

The system provides real-time weather, road conditions and maintenance information to supervisors and snowplow operators to help them make decisions about salt, sand and chemical use. The system also helps managers in the efficient distribution of drivers and equipment.

The Maintenance Office has used the MDSS system for years, but it was in the development and testing stages. The technology is combined with the Automated Vehicle Location technology and mobile data computers. The AVL supports MDSS by continuously recording plow truck locations, spreader controllers and road and air temperatures. The mobile data computers process and send data to host servers from the truck. Together, these three technologies are a powerful tool that assist MnDOT operators and supervisors in managing each unique winter event.

“All the pieces are now in place for MnDOT to use the system as it was intended,” said Joe Huneke, road weather technology section supervisor. “In the road weather technology world, this is what we’ve been working toward for a long time.”

MDSS helps snowplow operators determine the correct amount of materials to apply to the roadway surface, which many times is less than what operators would normally apply. That lessens the environmental impacts of salt and chemical use and there can be significant financial savings.

The AVL screen, located in the snowplow, supports MDSS by continuously recording plow truck locations, spreader controllers and road and air temperatures. |

Those savings can include reducing snowplow passes, which saves time, fuel and equipment wear and tear. Information from the MDSS system goes directly to the trucks via the AVL system, giving operators up-to-the-minute weather and treatment recommendations without returning to the truck stations.

Operators can also input road and weather information, and the system automatically collects information such as pavement and air temperatures. MDSS translates all the data into a pavement model and provides recommendations back to the truck within a few minutes.

The system uses all this information to make recommendations unique to each individual route, Huenke said.

“The more information we can provide from the truck to MDSS, the better. This helps the logic of MDSS to create efficiencies,” he said. “Using MDSS in tandem with the AVL and mobile data computers has the potential to produce dramatic savings and help manage our snow and ice records.”

Savings in 2015 was estimated at $380,000 when the system was partially activated. By 2020, the system is expected to save an estimated $5.8 million annually.

Huneke said the system is capable of providing reports of salt and materials usage on each plow route. The reports are available to operators in the vehicle at the end of the shift. Reports can also help with speed compliance of plow operators while applying materials. This helps keep more material on the target area of the road for more efficient melting.

“The system shows us how we managed a winter event and helps us learn how to manage the next one more efficiently,” Huneke said.

Nearly 75 percent of MnDOT’s snowplows are equipped with MDSS, he said. By 2020, MnDOT’s entire snowplow fleet will be outfitted with MDSS.

A grant from the Federal Highway Administration helped MnDOT implement the system. In return, MnDOT provides data to FHWA, National Weather Service and the National Center for Atmospheric Research. |

|

|

|

|

TABLE of CONTENTS

|

2016 season ends for Upper Mississippi River shipping |

|

By Marcia Lochner, Office of Freight & Commercial Vehicle Operations

The David L. Fields towboat waits on the Mississippi for the last barges of its tow before leaving St. Paul Dec. 1. Photo by Patrick Phenow |

Another shipping season came to its end on the Upper Mississippi River Dec. 1. The David L. Fields towboat was the last tow to leave St. Paul late in the evening heading for St. Louis, Mo. The tow pushed six barges loaded with grain, scrap and Distiller’s Dried Grains.

Although final tonnage figures are not tallied for the river’s five ports, the Saint Paul Port Authority reports a great shipping year.

“We expect 2016 tonnages to be close to six million tons through the port of Saint Paul,” said Kathryn Sarnecki, vice president of Redevelopment and Harbor Management for the St. Paul Port Authority. “This is a significant increase for us, which we suspect is mainly due to the great growing season for agricultural products over the last two years.”

Minnesota shipped more than 3.4 million tons of grain down the river in 2015. The river ports also handle other dry commodities, such as fertilizer, cement, sand, gravel, salt, coal and steel, and liquid materials such as petroleum, caustic soda, vegetable oils, molasses and anhydrous ammonia.

The Mississippi River Navigation System is maintained by the U.S. Army Corps of Engineers. The Corps dredges the width and depth of the channel to accommodate 9-foot deep barges, and they operate the 29 locks and dams on the Upper Mississippi.

The locks are also used by recreational boaters at no cost. The commercial barge operators on the river pay a user fee of 20 cents per gallon of fuel purchased. These dollars are then used to pay for half of major federal lock structure improvements.

For more information, visit MnDOT’s Ports and Waterways website. |

|

|

|

|

TABLE of CONTENTS

|

MnDOT adds North Star Route to U.S. bicycle system |

By Sue Roe

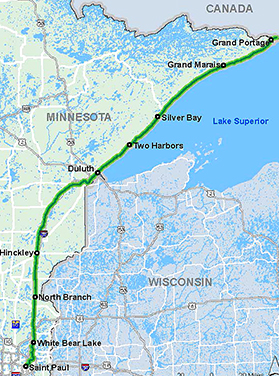

Map shows the route of U.S. Bicycle Route 41 from St. Paul to the Grand Portage State Park. |

A 315-mile bicycle route between St. Paul and Grand Portage State Park, near the Canadian border, is the state’s second route to be listed on the U.S. Bicycle Route System.

The route, which is U.S. Bicycle Route 41, will also be known as the North Star Bicycle Route. The public selected the name during MnDOT’s public engagement process to align the route.

The U.S. Bicycle Route System is a network of numbered cross country routes. Currently there are more than 11,500 miles of U.S. Bicycle Routes in 24 states.

Minnesota’s first U.S. Bicycle Route is the Mississippi River Trail, which goes from Hastings to the Iowa border. It was designated in 2013. The MRT is also known as U.S. Bicycle Route 45.

The new North Star Bicycle Route combines existing roads and mixed-use paths and trails that travel through some of the state’s most popular locations, including two national parks, nine state parks and the Superior National Forest. The route also passes through two nationally recognized bicycle friendly communities, Duluth and Grand Marais.

“With nearly half the route on trails, there are many opportunities for families and less-experienced bicyclists to travel and enjoy the route,” said Liz Walton, project manager from the Transit Office. “Also, on a bicycle, there are opportunities to experience the many cities with small-town charm that people miss when traveling on the interstate highway. The route will contribute to more vibrant and healthy communities for those who that take full advantage of bicycling for travel and fun. Bicyclists, businesses and others stand to benefit.”

She said MnDOT is committed to a long-term partnership with the communities and road and trail authorities along the route.

“MnDOT will be a strong partner to support and expand the off-road bicycle network,” Walton said.

A ribbon-cutting is planned May 20, 2017 at the junction of U.S. Bicycle Routes 41 and 45 in St. Paul, which will kick off a six-day bicycle ride to Grand Portage State Park.

Read more about the North Star Route and the May bicycle ride at www.mndot.gov/bike/usbr41/index.html

|

|

|

|

|

TABLE of CONTENTS

|

WIG 2.0 Focus Area Highlight: Internal Customer Engagement is helping advance customer trust |

By Judy Jacobs

Sue Stein leads the WIG 2.0 Internal Customer Engagement focus area. Photo by Judy Jacobs |

One of the four focus areas of WIG 2.0 is Internal Customer Engagement. This includes the goals of Improving Customer Involvement, Considering Customer Impact and Improving Customer Experience. This focus area challenges employees to think about how we communicate and interact with our coworkers across the state as we shift to having a more customer-centered workplace.

"Research shows that before organizations can successfully improve their external customer engagement, they must first provide a positive internal customer experience," said Sue Stein, assistant commissioner, Corporate Services, and champion for the Internal Customer Engagement focus area. "When we all work together to provide a great internal customer experience, it leads to a great customer focus for our external customers as well."

As part of this effort, the WIG 2.0 champions are conducting a survey that includes all MnDOT employees and is directed at both internal and external customers to establish a baseline. This baseline will help workgroups determine how they, as a team, can work towards improvements in customer engagement. This is a coordinated effort across the state, designed to avoid multiple areas in the agency surveying each other and to prevent “survey fatigue.”

It’s not too late to complete a survey! It only takes a minute and will help us define our next steps as an agency. Your opinion matters to us. Look for the link to the survey in the signature box. |

“Once we have established an overall baseline, we’ll set our improvement goals,” said Stein. “We will provide resources for customer-centered best practices and techniques. We may also consider launching a mentoring program, a customer recognition program or creating a place on iHUB to highlight employees who are customer-centered.”

Plain language is an important part of this focus area. Plain language is communicating so your audience understands the message the first time they read or hear it.

Improving Customer Involvement

One goal area directly affecting the Internal Customer Engagement focus area is Improving Customer Involvement.

Employees from District 3 Administrative Support Staff recently toured various offices in C.O. to meet, and help better understand, their internal customers. From left: Cindy Senger, Becky Vernier, Kristy Barhorst, Linda Ritzenthaler and Lori Carry. Photo by Janice Kiley |

“When we think about our customers, many times we think about external customers,” said Betty Jo Winterowd, District 3 administration manager, and champion of the Improve Customer Involvement goal area.

“However, we also have many internal customers. They are your coworkers who rely on you for information and products so they can perform their job. We all have internal customers at various levels throughout the organization.”

“Once we identify our customers, getting them involved so we understand their needs will be a very important factor to ensuring they are engaged,” said Winterowd. “One of the best ways to determine if we’re meeting customers’ needs is to ask for feedback. It’s also critical to develop good solid working relationships so our customers are comfortable approaching us and giving us direct feedback about their experience working with us.”

Consider Customer Impact

Another important component of the Internal Customer Engagement focus area is to Consider Customer Impact.

“Considering customer impact is about how an action or a decision affects or changes the customer’s daily work and how that action or decision addresses the customers’ needs,” said Jean Wallace, assistant division director, Modal Planning and Program Management, and champion for the Consider Customer Impact goal area. “The outcome can be different for every customer, so it’s important to involve our customers before we make our decisions so we better understand how our work could impact them and their ability to do their jobs.”

“Considering customer impact is a two-way discussion that includes active listening to understand the impacts of our decisions and actions,” said Wallace. “As we work in our WIG teams, and as part of a respectful workplace, it’s important to ensure that we implement processes and practices that will gather the information we need in order to consider customer impact. It’s also important to be open to diverse opinions and ideas from our internal customers to provide a positive customer experience and deliver the highest quality work and best products to all customers.”

In a recent training on creating a Customer-Centered Culture, more than 50 MnDOT managers, WIG coaches and champions learned that by having a customer-centered mindset, and through strengthening our actions to consider customer impact, employees can build stronger working relationships and more engaged internal customers.

Improve Internal Customer Experience

The third goal area under the Internal Customer Engagement Focus Area Is to Improve Internal Customer Experience.

“As we conduct our daily business at MnDOT, it’s important that we’re mindful of our interactions with our coworkers. These are our internal customers and their work contributes directly to MnDOT’s success as an agency,” said Tom Styrbicki, Project Management and Technical Support director, and champion of the Improve Internal Customer Experience goal area. “How do we not only meet their needs, but serve them in a way that is respectful, professional and truly focused on delivering the best possible customer experience?”

“As we strengthen these internal interactions, we’ll build a more efficient and engaged MnDOT team,” said Styrbicki. “Together we’ll achieve our Wildly Important Goal of Earning Customer Trust.”

Stein said that each WIG team can play a part in Earning Customer Trust by improving customer involvement, considering customer impact, and improving MnDOT’s internal and external customer experience.

“We will be successful when we can say, ‘Great customer engagement isn’t what we do; it’s who we are,’” she said.

|

|

|

|

|

TABLE of CONTENTS

|

Operations, Engineering Services implement new program for shared real estate services |

By Rich Kemp

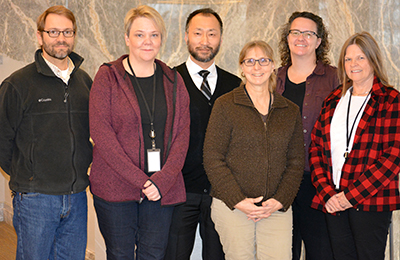

The new Real Estate Shared Services section includes, from left, Josh Kelly, Central Office; Melissa Janzen, District 3; David Funck, Central Office; Debra Filipovich, District 1; Julie Groetsch, Real Estate Shared Services supervisor; and Cindy Morris, Central Office. Photo by Sue Roe |

The Operations Division has partnered with the Engineering Services Division to implement a new shared services program in the Office of Land Management to help districts deliver appraisal, direct purchase and relocation functions.

The real estate shared services program is one of several shared service programs that include Intelligent Transportation Systems design, signal and lighting design and signing design.

Marilyn Jordahl Larson, who established the shared services program, works with a steering committee that includes Amr Jabr, Operations Division assistant director; Bryan Dodds, Metro District Operations and Maintenance director; Joseph Pignato, Office of Land Management assistant director; Steven Kirsch, District 6 assistant district engineer, Program Support; Debra Anderson, Metro District Right of Way manager; and Julie Groetsch, Real Estate Shared Services supervisor.

“The new real estate shared services is a tool that affords districts greater flexibility and the opportunity to enhance planning and project delivery,” said Kirsch.

Larson met with right of way staff from the districts to determine their appraisal, direct purchase and relocation needs. Based on their responses and guidance from the steering committee, five new positions were created to staff the new Real Estate Shared Services section.

To establish the Real Estate Shared Services section, Groetsch added Cindy Morris, Debra Filipovich, Melissa Janzen, David Funck and Josh Kelly to her team.

”I am excited to manage the Real Estate Shared Services Unit,” said Groetsch. “I’ve got five quality employees who are able to help acquire right of way for districts around the state. At this point, we are scheduling our work through calendar 2017, so districts need to request our services as soon as they can.”

“Our next focus area will be using a shared service for leasing and turn backs,” said Larson. “The steering committee is working with the Office of Financial Management to set up the funding structure for the next biennium.”

All shared services guidance documents and request forms are available on the iHub at the Shared Services site.

The Shared Services concept is an organizational approach that is focused on building efficiencies and reducing redundancies so that services can be provided on behalf of the entire organization. It is not intended to decrease MnDOT’s complement, but rather provide relief from the heavy program delivery workload experienced by district staff.

“Using shared services adds significant efficiency to the department,” said Jabr. “Some processes are not commonly used by some districts (for example, designing traffic signals). And, there is high demand but not enough resources for other processes (for example, appraisals). For those processes, we create a Shared Service group that specializes in that particular process and therefore can perform it for any district or office quickly and with very high quality.”

The Operations Division is open to applying the shared services concept in other areas. Relay your ideas to Marilyn Jordahl-Larson at 651-366-4666. |

|

|

|

|

TABLE of CONTENTS

|

What’s new on the web |

Public Engagement and Constituent Services webpage

In conjunction with the recent approval of MnDOT's new Public Engagement policy, the Office of Public Engagement and Constituent Services is launching a new iHUB site with a wide range of professional resources, tips, best practices and contact information for questions related to the policy and public engagement in general.

The OPECS site will be continually updated based on your feedback and to provide ongoing support to the WIG teams working on activities related to improving intentional customer engagement. Contact OPECS Director Richard Davis to share your thoughts.

New online form simplifies requests for communications assistance

MnDOT employees now have a new way to request communications assistance. From simple request, such as needing a poster to advertise an upcoming event, to complex needs for communications planning for a new initiative, the place to start is by filling out the communications request form at http://ihub/communications/communicationsform.php.

The new form allows MnDOT staff to ask for help from the comfort of their own desktop and will allow Communications staff to better track and schedule work. Employees will be asked to include information about what objectives they want to accomplish through communications. Understanding the ultimate goal will help communication planning staff chose the best tool for the job.

Simple requests for updates to existing webpages or graphics can still be sent to webteam.dot@state.mn.us.

Video tutorials provide visual support for oversize/overweight permit customers

The Office of Freight and Commercial Vehicle Operations has posted a series of video tutorials on its website to help customers use the routing portion of MnDOT’s online oversize/overweight permitting system.

Gary Andrist, Video Services team leader, Marcia Lochner, OFCVO Communications, and Rob Holschbach, OFCVO transportation program specialist, discuss routing video scripts. Photo by Joel Wenz |

Rob Holschbach, transportation program specialist in OFCVO’s Oversize/Overweight Permits section, initiated the project and produced it with Video Services and Marcia Lochner, OFCVO Communications, to teach customers how to plan and enter the routes their OS/OW loads will travel through Minnesota. This effort will also improve efficiency in the office by reducing the quantity and duration of calls OFCVO receives from customers requesting assistance with the routing process.

“None of this would even have been possible without Marcia Lochner and Gary Andrist’s time and energy to help in putting these together,” said Holschbach. “I’ve been very excited about this project since the beginning and believe these tutorials will prove to be an excellent educational resource for the industry to help them understand the routing process and save them valuable time.”

“I really enjoy working with clients like Rob and Marcia who are invested in their project and have a clear mission and message that they want conveyed to their viewing audience,” said Andrist, Video Services team leader. “I appreciate their creativity and input in the production process.”

To learn more about OFCVO’s OS/OW Permits section and check out the videos, go to mndot.gov/cvo/oversize.

New Library Materials

New Library Materials are available at www.mndot.gov/library/newlibmat.html. This issue is the last one of the year. The Library staff wishes you a Happy Holiday and looks forward to serving you in 2017.

New Library Materials is a compilation of new titles and other resources added to the library collection during the previous month. If you would like to be added to the distribution list, contact Pam Gonzalez at 651-366-3749.

Previous editions of New Library Materials are available at www.mndot.gov/library/recacq-archive.html.

For other information requests, contact the Library at 651-366-3791 or email library.dot@state.mn.us, or send requests via the Ask a Librarian Web page at www.mndot.gov/library/asklibrarian.html. |

|

|

|

|

TABLE of CONTENTS

|

On the job: District 4’s Rick Johnson helps keep plows on the road |

By Jerimiah Moerke, District 4 public affairs coordinator

Rick Johnson works with a team of nine mechanics to keep the snowplows on the road in District 4. Photo by Jerimiah Moerke |

This time of year, MnDOT’s snowplows are the most visible sign of the department’s work. And behind every snowplow in the state is a team of mechanics working to keep them running through the harshest winter conditions.

Rick Johnson is one of nine mechanics based in District 4.

He started at MnDOT in 2013 after working nearly 30 years as a mechanic for a Detroit Lakes auto dealership.

While Johnson enjoys his work at MnDOT, he says nothing can prepare you for the “pink snowman.” That’s when a piece of snow and ice equipment comes into the shop covered in pink snow. It’s a sure sign of a hydraulic leak. Johnson and his colleagues have to clear the snow and figure out which of the 20 to 40 hoses is the problem. It’s not his favorite task, but it’s important.

What is the most important aspect of your job?

Working as a team to repair every component of the snow and ice equipment.

We spend a lot of time starting in April until Oct. 15 when the plows need to be ready. They start showing up in April for the commercial vehicle inspection and preventive maintenance inspection. We inspect the trucks bumper to bumper and we have an additional checklist of known trouble and modifications needed from operator reports and problems found in other districts. The field mechanics complete the first inspection called the “snow and ice sheet” on the trucks which they are responsible for. Then it’s up to the supervisor to decide if we fix or retire the equipment.

What surprises have you encountered?

I am surprised at our ability to make parts to modify and repair our equipment. And a lot of times you have to make a tool to get the job done.

For example, I made a couple of tire tools after two years of wrestling with 24.5” tires and rusted on wheels. I shared my idea at the 2016 Heavy Equipment Mechanic conference in St. Cloud and received the “Best Idea Award” representing District 4. The tools are very helpful, and I’m glad I was able to share the idea with others. But standing in front of 60 people is way outside of my comfort zone.

I was also unaware there would be so much welding, cutting and bending metal—and of course, rust. Our goal is clear—make it work and make it safe; take pride but it isn’t always pretty.

What have you been working on lately?

Right now, I’m setting up a tow plow. There’s a lot of set-up and modifications to make it better for the operator. For example, hooking up hydraulic lines, the electrical and the brine system controls. We get a lot of instructions on how to set it up and it takes a while.

What’s the biggest change you’ve seen in your years as a mechanic both inside and outside of MnDOT?

Computer technology. I was a heavy line mechanic for my first 20 years. I did all the engines and transmissions. So I had had a pretty good mechanical background. Then as technology came along, the computers were pretty overwhelming. Every manufacturer has a different computerized platform and so you have to learn them all.

What’s been your most unique experience at MnDOT?

Last winter, I got put in the field service truck in a blizzard. One of our field mechanics was out, and there was a truck out on Hwy 32 with no air.

I had to figure out if I could fix the air leak on the side of the road to get the truck back to the shop for a proper repair. The truck was set off with the cones, sitting there in the middle of nowhere. I was able to pull up and see the problem. I did a few cuts and a splice, and had him start it up. There were no air leaks, so I said, “I’ll follow you into town.” That was unique for me.

Just working out of someone else’s toolbox is a challenge.

Do you or a co-worker have an interesting job to share with readers? Send us your ideas, and we’ll contact you for more information.

Recent employee profiles:

|

|

|

|

|

TABLE of CONTENTS

|

Vacation Donation program helps families through tough times |

By Joe Sass, MN.IT Services information technology specialist

Joe Sass, vacation donation recipient, is pictured with two-year-old daughter Hadley, who received part of his liver 10 days before this photo was taken. Sass and his family are very appreciative of the vacation hours donated by employees. Photo courtesy of Sass family |

Last April, cancer sent my beautiful, smart, sassy and silly almost-two year-old daughter to Pediatric Intensive Care Unit at Children’s Hospital Minneapolis. Her condition quickly deteriorated and machines were necessary to manage her breathing and other bodily functions, while she remained sedated for what would turn into several weeks. There were awful moments where I sat next to her hospital bed, holding her hand and wondering if I would ever get to hear my daughter talk or even see her smile again.

The type of cancer that Hadley was diagnosed with is very rare in children, and often deadly in adults. But children have a resiliency that’s often not found in adults, and fighting cancer is no exception.

Thanks to the incredibly skilled care of her doctors and nurses, Hadley’s own personal strength, and perhaps some divine intervention, she got better and one by one the machines supporting her were able to be shut off and removed. With therapy, Hadley regained her strength, began talking again, and relearned how to walk and swallow. Finally after two months, she got to leave the hospital and go home.

I was able to return to work for a short amount of time, too, while Hadley was undergoing out-patient chemotherapy and while we waited for the doctors to decide the next step in Hadley’s treatment. When I came back to work, the amount of support that I received from my coworkers was overwhelming – I had never been hugged so many times at work before!

Throughout this ordeal, I had felt like a spectator watching on the sidelines while the doctors and nurses worked to save Hadley’s life. In September, though, I finally got a chance to help Hadley – in the form of a liver transplant. During simultaneous operations, surgeons removed a portion of my liver, removed Hadley’s entire liver (and with it all of the cancer) and placed the portion of my liver in Hadley. Today, Hadley and her new liver appear to be doing great.

Hadley has spent over 80 nights in the hospital. This doesn’t include the countless days that she has been in various clinics receiving chemotherapy, blood transfusions and other treatments, the multiple trips we have taken to the Mayo Clinic and to Chicago for the transplant, or the month when we lived at the Ronald McDonald House. From April until November, it was nearly impossible for me to work.

Parents of critically ill children are placed in an incredibly tough position: they must care for their sick children, while still trying to maintain the other aspects of everyday life. Bills still need to be paid. As the sole source of income for my family of 5, I couldn’t help but wonder how we were going to pay for things. The statistics say that 1 in 11 families with a child diagnosed with cancer files for bankruptcy. Without the Vacation Donation program and the generosity of everyone at MnDOT and MN.IT @ DOT, my family could easily have been included in that statistic. The Vacation Donation program and the unwavering support of my coworkers took away that burden for me. I did not have to worry about how I was going to support my family and, instead, I was able to be present and focus on being a loving father.

How can I possibly say thank you to everyone who helped my family get through this? Whether you donated your vacation time, gave me a hug, shared words of hope and encouragement, or even just smiled at me in the hallway, please know that you made a difference during this incredibly difficult time and I am forever grateful.

Editor's note: To donate vacation hours, go to the Employee Self Service Web site and click “Other Payroll” and then “Leave Donations.” The site also allows employees to view a list of all state employees eligible for the program and to enroll as a recipient.

Current MnDOT employees in the Vacation Donation Program include Curt Pape and Paula Erickson. |

|

|

| |

|