|

By Mike Dougherty, District 6 public affairs coordinator

Chade Trupe, District 6 transportation materials technician in the Rochester Inventory Center, built a hydraulic inspection vehicle explorer from equipment and parts from a hobby shop and hardware store. He is building more HIVEs for other MnDOT districts. Photo by Mike Dougherty |

An idea for more efficient and effective culvert, pipe and catch basin inspections in District 6 that had percolated in the head of Rob Coughlin came to life in 2015 and is now rippling out to other MnDOT districts.

The Hydraulic Inspection Vehicle Explorer or HIVE is the creation of Coughlin, a water resources inspector in Rochester, and Chade Trupe, a transportation materials technician in the District 6 Rochester Inventory Center.

Their first effort is nearing its one-year anniversary in May. Trupe built one recently for water resources in the Metro District and is in the process of building a HIVE for District 1. Each vehicle costs approximately $1,500. The inspector needs a tablet for video viewing in the field. Contrast that with a full fiber-optic video inspection unit that requires multiple people and equipment that can cost upwards of $80,000, according to Coughlin and Trupe.

The two collaborated to modify a radio-controlled vehicle with a camera, lights and retrieval line to allow just one inspector to review and analyze the conditions of culverts, pipes and catch basins with a much greater thoroughness and much less expense. It is also smaller than the typical camera and can fit in tight spots where the traditional camera cannot fit. It is also waterproof, so it will help in many situations where there is standing water in pipes or culverts.

Coughlin was seeking a low-cost, efficient way to improve his inspection efforts when a worker could not enter for a full visual inspection because of the size of the pipe or the degree of difficulty. Larger video inspection units are available through MnDOT, but are in demand and scheduling can be challenging to meet each district’s full needs.

Collaboration

Last year, Coughlin was talking about the plans with Trupe and Mark Hill, who are in the Rochester Inventory Center. It turns out that Trupe and Hill both are long-time radio-controlled car enthusiasts, who build and repair their own vehicles, while also competing in race events.

Soon, Trupe was developing a product based on Coughlin’s needs and initial plans.

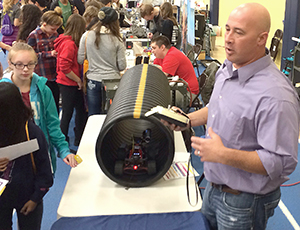

Rob Coughlin, a District 6 water resources inspector, explains to students at a Rochester STEM Summit how the hydraulic inspection vehicle explorer works. Photo by Mike Dougherty |

Coughlin headed out into the field in May 2015 with a radio-controlled car rigged up to give him an inside view. He totes the entire operation around in a cardboard box.

“I can pull this out of the truck and be set up in minutes to inspect,” Coughlin said. “I use it every day.”

Coughlin has a Sony action camera mounted on the car, which also has spotlights. The camera and lights can be moved around via the radio controls. A Wi-Fi connection sends the signal to Coughlin’s tablet for viewing and recording. It uses a retrieval line in case the vehicle tumbles into a hole and it has a red rear light for tracking its progress into a dark pipe.

He’s documented 60 pipes and looked over about 100 so far. He said it’s been mainly used in scoping work, but can be used for various needs.

“We’ve had trial and error, but you learn a lot as you use it,” Coughlin said.

Helping out

Trupe is quick to credit the teamwork in the inventory center. Trupe’s supervisor, Pete Czaplewski, said it was a chance for inventory to contribute to MnDOT’s efforts in a different way.

“We really have a good team with Carl (Evers) and Mark who can help out to give Chade the time to do this as it demands,” Czaplewski said. “We manage it, but it takes everyone willing to do what needs to be done.”

Trupe said his goal is to complete the future builds in six to eight hours. His initial effort took about 13 hours, but he said the first one for Coughlin was custom made, whereas the follow-up versions are off the shelf and he knows what’s needed to build a HIVE.

Hill is assisting in cataloguing the parts and assembly steps electronically, so that they can be shared and replacement parts can be quickly purchased, if needed.

Trupe has worked with radio-controlled vehicles since he was 14. He’s got seven vehicles at home.

“It’s my passion,” he said. “I’ve done it for 32 years and love it.”

What he likes about this project is that he’s participating in something that helps the district do its job better and saves money.

“It’s a true means of saving money,” he said.

And while it might end up resulting in finding more repair and replacement needs for culverts, pipes and catch basins, it’s more likely to find the pipes and culverts in a time where it’s more efficient to schedule those repairs into a planned project along the roadway. Discovering the needs in an emergency situation is far more costly and dangerous.

Coughlin has already seen the results of finding pipes and culverts where there’s damage in an area he wouldn’t have likely been able to detect in the past. With the visual confirmation, they can determine the full need of the repairs and the timeliness of when it’s needed.

MnDOT usage

The Metro District sought a vehicle to get accurate cost estimates at the time of project scoping.

“We need to be able to view inside the pipes, culverts and catch basins to determine what repairs or replacements need to be made,” said Beth Neuendorf, Metro District water resources engineer.

Cost estimates are based on the infrastructure condition information from the videos.

“The remote-controlled vehicle with camera will be used where we don’t have adequate information at the time of scoping,” Neuendorf said. “There is a backlog of projects that need video inspection services and we are unable to completely fulfill those needs via other methods. The remote controlled vehicle and camera will also be used in instances where we have emergency situations where we need immediate answers to pipe and culvert repair options.”

Trupe said the building of Metro’s vehicle went much faster than the initial D6 vehicle. He’s got a small work station tucked back in the Rochester Inventory Center with parts and tools needed for assembly.

“This is a hobby-grade vehicle that’s designed to take a lot of abuse and go lots of places,” he said. “I’m very honored that we were able to put the work into it and that it’s gone over as well as it has.” |