|

|

|

|

TABLE of CONTENTS

|

Project update: District 4 uses cold-in-place recycling to repair Hwy 29 |

By Jerimiah Moerke, District 4 public affairs coordinator

Crews work to replace a bridge on Hwy 29 south of Benson. Despite a lot of rain, the bridges were completed ahead of schedule. Photo by Joe Denny |

Drivers in the Benson area are anxiously waiting the re-opening of a key highway in west central Minnesota.

A major resurfacing and bridge replacement project on Hwy 29 south of Benson is on track for completion by the end of September. The highway has been detoured since late July.

Work was originally scheduled to begin in 2015 but was moved up because of the condition of the 14-mile stretch of Hwy 29, which had severe cracking.

Not only will the quicker timeline leave a smoother road at an earlier date, it also will reduce the amount of time and material needed to repair cracks and potholes on the highway.

The project involves a cold-in-place recycling and the replacement of three bridges.

Bridge work

Despite eight to nine inches of rain in early August, the three bridges are essentially complete.

“The bridges went together rather nicely—ahead of schedule,” said Dan Kuhn, District 4 bridge engineer.

Kuhn and project supervisor Brad Cegla credit good coordination by the bridge contractor, Redstone. The largest bridge was complete in five weeks. The other two bridges were replaced with box culverts.

Cold-in-place recycling

The resurfacing portion of the project used cold-in-place recycling, which is a longer-term fix than a traditional mill and overlay.

In cold-in-place recycling, crews remove the top layer of pavement. After the top layer is removed, they mill several more inches of existing pavement, mix it with an oil-based solution and replace it right at the construction site. Then a new layer of bituminous is placed over the top. Cold-in-place recycling is meant to reduce the amount of maintenance and repair costs over time.

For this project, crews used ground-penetrating radar to estimate the thickness of the existing pavement.

“If it was too thin, we could adjust the mill depth,” Cegla said. “We adjusted the depths in quite a few spots.”

Central Specialties, Inc., of Alexandria is the prime contractor for the $7 million project.

|

|

|

|

|

TABLE of CONTENTS

|

Birth of a roundabout: District 7’s Hwy 22 in Mankato |

By Rebecca Arndt, District 7 public affairs coordinator

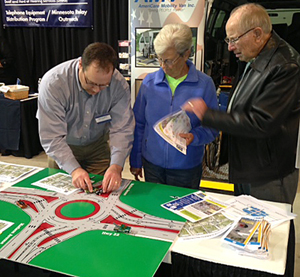

At a recent Senior Expo, Glen Coudron, project manager, explained how to drive the multi-lane roundabouts using matchbox cars and a table-top display. Photo by Rebecca Arndt |

The plan develops…

The concept of a multi-lane roundabout at a high-traffic, high-crash intersection in Mankato’s retail area was not MnDOT’s idea. The city planned to reconstruct Madison Avenue and saw an opportunity to partner with the state to improve the avenue’s intersection with Hwy 22. In 2009, the city approached MnDOT with the roundabout idea.

“I thought – no way, but after a lot of research and analysis, it became clear that it was a very viable option,” said Scott Thompson, District 7 traffic engineer. “Then further investigation determined it made sense to also build a roundabout at the next downstream intersection with Hwy 22 – Adams Street – District 7’s highest crash intersection.”

The roundabout concept created much discussion with local officials, generating many headlines. Area leaders started to accept the idea after presentations from and discussions with MnDOT staff, and after researching a similar project in Richfield.

The next stakeholders to get on board were the area businesses. Several open houses and one final meeting brought most everyone to the agreement that if both intersections can be built in one short season (before holiday shopping), there would be success.

Educating the drivers and employees…

When the District 7 Public Affairs office learned of the plans for two multi-lane roundabouts on Hwy 22, there was concern that it was too much.

As the plans for the two roundabouts took shape, more drivers were becoming comfortable after the idea with the introduction of numerous smaller roundabouts in the area.

The city, county and MnDOT public information representatives created a partnership before the opening of the first roundabout at a county intersection in Mankato. They used newsletters, news releases, videos, events, local cable access, websites and contacts with driver education to get basic roundabout methods out to the public.

Educating the driving community meant educating all employees first – not only at MnDOT, but at the city and county as well. Everyone needed to be able to talk about the project and driving multi-lane roundabouts. The agencies used newsletters, displays and presentations to key groups, such as area law enforcement, to help get the word out.

MnDOT District 7 jumped on an opportunity to join the local senior driving improvement program instructor (and Toward Zero Deaths member) at the Mankato Senior Expo. MnDOT brought plans and toy cars and handed out highway maps (with the roundabout diagram on the back), and senior citizens lined up around the corner. Thompson, who had lost his voice by noon, was replaced by Zak Tess, District 7 project manager, for the afternoon shift.

After District 7 employees built a replica of one of the roundabouts, more than 500 attendees were able to ride with an engineer on a golf cart or drive the golf cart with the engineer as a guide. It was the premier event for getting the community ready for the Hwy 22 roundabouts. Photo by Rebecca Arndt |

The Senior Expo was repeated two more years with a larger booth, more TZD partners, roundabout rugs, table displays and handouts. The first year, the majority of visitors “hated” roundabouts for a variety of reasons. The second year, attendees were split 50-50, and last spring (just prior to construction), an estimated 70 percent were in favor of roundabouts. About 1,500 seniors attend the expo each year. Giles Abbe, District 7 roundabout expert, created a rug as an exact replica of the roundabout being built at Hwy 22 and Madison Avenue.

A team approach…

While the partners in the project (MnDOT, Mankato and Blue Earth County) had retained a design consultant, including a marketing firm, getting the message out about the construction and driver education became a team approach.

“We really tried to reach everyone we could with a variety of techniques from brochures and videos to more creative walkable rugs, tours and hands-on driving experiences,” said Greg Ous, District 7 engineer.

Some of the products the team created were:

- A roundabout kiosk with videos, brochures, maps and contact information at a nearby mall (in place for nine months

- Saturday mall event with the replica rug and table top displays - staffed by all partners who made contact with several hundred people

- Website, www.roundaboutready.com, loaded with info, driving videos and webcams

- A ride the roundabout bus tour – the city provided a vehicle to market their buses to new users. Ous promoted the event on Mankato radio.

- Roundabout rug display with video in the MnDOT rotunda for six months to catch new drivers and parents visiting DVS (photo)

- Three full page ads (offered by the daily newspaper at a fraction of the cost) and radio promotions

-

Detour map and construction schedule (May)

-

Promotion of roundabout fair/bus tours and driving tips (July)

-

Detailed driving diagrams (August)

- Ride the Roundabout Fair – 900 to 1,000 attendees

- Replica roundabout driven with golf carts and roundabout experts

- Table top displays

-

Roundabout games (quiz)

-

Bus tours of nearby roundabouts – the bus filled up seven times!

-

TZD exhibit

-

Free hot dogs

Special weapon

After some turnover in the marketing office, the consultant provided a fulltime staffer in Mankato, who spent the summer as point person for all messaging. In addition to coordinating the events above, the point person visited drivers education classes, attended area events, made videos for local businesses, kept the website current, took phone calls and hosted business meetings. Ultimately, that role helped the team maintain a positive relationship with the affected businesses and the local media throughout the project.

Opening…

Increased safety and decreased delay was the motto and, to date, it has been successful.

The opening of the first roundabout at Adams Street took place in July and the Madison Avenue roundabout opened in August with only a few minor property damage reports to date.

With delays significantly reduced at two major intersections, the city of Mankato took the saved time and applied it to a much need expansion of one of its bus routes to a specialty medical center.

“Considering all the hurdles we went through, I think the project went as well as it could,” said Glen Coudron, District 7 project manager. “With everyone’s help from planning through construction, we were able to make it come together. And now that the construction is completed, it is even more special to receive compliments from people who initially were skeptical.” |

|

|

|

|

TABLE of CONTENTS

|

Pedestrian safety fall campaign focuses on college students |

|

By Kristin Kammueller

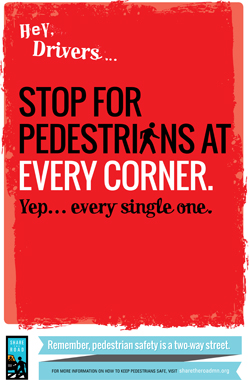

This is one of the ads that will appear in restaurants and bars near eight Minnesota colleges in September and October. It is part of the pedestrian safety campaign that is going on around the state. |

In an effort to continue to raise awareness of pedestrian safety the Office of Traffic, Safety and Technology has launched the fall pedestrian safety campaign.

Unlike the summer campaign, the fall campaign has a statewide focus, specifically targeting college students.

“For the spring campaign we were very focused with our messages in St. Paul,” said Sue Groth, state traffic engineer. “For the fall campaign our goal is to reach a larger audience.”

The $115,000 campaign includes 30-second radio spots that will run on radio stations across the state between Sept. 15 and Oct. 5, bathroom ads at restaurants and bars within walking distance of eight college campuses around Minnesota, and street teams that will visit seven college campuses during the next couple weeks, talking to students and handing out pedestrian safety information.

The campaign tactics are expected to have more than 4.5 million impressions, meaning a lot of people will hear and see the pedestrian safety messages. |

|

|

|

|

|

|

TABLE of CONTENTS

|

Pavement performance workshop promotes further partnership |

|

By Shannon Fiecke, Research Services & Library

Michael Trentacoste, director of the federal Turner-Fairbank Highway Research Center, spoke at the Midwestern Pavement Preservation Partnership forum Sept. 4. Photo by Shannon Fiecke |

Pavement engineers from around the nation met in Minneapolis Sept. 2–5 for the Midwestern Pavement Preservation Partnership forum and the SHRP2 R26 Workshop for the Preservation of High-Traffic-Volume Roadways, which featured tours of MnROAD, Minnesota's cold weather pavement testing facility.

Participants also learned about a proposed partnership between MnROAD and the National Center for Asphalt Technologies in Auburn, Ala., the hot weather testing facility equivalent of MnROAD. Federal highway officials were introduced to the proposal, which is intended to advance pavement preservation techniques throughout the country.

"By working together we can maximize the potential for each track," said Ben Worel, MnROAD operations engineer.

In addition, participants reviewed the latest preservation techniques being developed for high-volume roads. MnROAD's chip sealing study, which demonstrated that highways with an average daily traffic of 58,000 can be successfully chip-sealed, was especially attention-grabbing for agencies that don't chip seal on roads with more than 2,000 ADT.

Attendees also heard from a national panel that included Michael Trentacoste, director of the federal Turner-Fairbank Highway Research Center, who discussed Federal Highway Administration's support of pavement preservation research and implementation.

With about 160 people in attendance over four days, MnDOT Materials Engineer Jerry Geib said the conference was successful in sharing the benefits of pavement preservation techniques with other state DOTs and federal highway officials who want adopt new practices to help alleviate budget constraints. |

|

|

|

|

|

|

TABLE of CONTENTS

|

On the job: Visual design duo create animations to help inform public |

By Rich Kemp

Marv Hondl (standing) and Kai Huot-Link work on animation video projects to help educate the public. Photo by Rich Kemp |

A dual threat in sports can make a team very successful. The same can be said in the Visual Design Imaging Office located at MnDOT’s Waters Edge Building in Roseville.

Marv Hondl and Kai Huot-Link are the team that creates animated videos for MnDOT projects around the state. They say the animations are a good tool to help get projects approved and to educate the public.

Marv has worked for MnDOT for 37 years. He worked in Water Resources, and Final Design before joining the animation and visualization projects office in 1997.

Kai worked in Video Services and with the Communications web team for five years and has been with MnDOT for 15 years. He moved to the Visual Design Imaging Office in 2004.

Do you work well together?

Marv: The comradery between us is what makes the job enjoyable. I really enjoy working with Kai.

Kai: Marv and I work well together and most of the time we both contribute to the same project. Animations are usually large road design projects. While I am creating one part of it, Marv can be designing another segment.

How does a project come about?

Marv: Usually a project engineer will come to us to request an animation or visualization product. We evaluate the end product with the project engineer to determine the best outcome.

What is the process for completing an animation?

Marv: We use up to six different software programs to complete a project. We start with a 2D design from the Design Section to produce a 3D cross section in the MicroStation 3D program.

Kai: We get photos and video to see what is actually at the site.

Marv: We are constantly working with other functional areas to find out what is needed in the animations.

Kai: Once we get the actual project design into the program, we start adding landscaping, buildings, lighting, pavement markings, signs, cars and people if needed. We keep tweaking it to try and make it look as real as possible.

Marv: We work with the project engineer to write the script and with Video Services to get music and to record the voice-over.

How long do the animation projects take to complete?

Marv: The projects can take two-three weeks, up to six months to complete.

What was your most unique experience?

Kai: For a project on I-35W, the State Patrol stopped all traffic on the freeway. I rigged up a camera mount on the roof of my car and drove down I-35W from about 46th Street to downtown. The State Patrol blocked the entrance ramps and stopped the traffic behind me. It was necessary to get a clear video of the freeway to serve as the background for the animation.

Marv: For the Lafayette Bridge project, we flew in a helicopter over the Lafayette Bridge and Mississippi River to capture video and photos. When we matched the animation to the video, it achieved a high level of realism.

What are some of the challenges of the job?

Marv: We work with so many software programs and constantly have to update the software on our rendering farm.

Kai: Rendering is very time consuming. We often break down a rendering job into multiple layers which are composited to create a finished frame. Rendering each frame could take from several minutes to an hour.

What are some of the positives or exciting parts of your job?

Marv: It is always challenging. It is rewarding when we get good feedback about the products we produce.

Kai: For me the most rewarding part is being able to build an animation from all the parts and see the results from your work.

What is your favorite animation that you have created?

Marv: The Lafayette Bridge animation was my favorite because we were able to get the video from the helicopter and match it to the animation.

Kai: I would have to agree that the Lafayette Bridge animation was my favorite. The St. Croix Crossing animation has also been interesting. We started it in 2004 with six different alternatives before they decided on a final option. We keep making additions and improvements to the animation.

Check out the animations created by Marv and Kai at their YouTube channel.

Do you or a co-worker have an interesting job to share with readers? Click here to send us your ideas, and we’ll contact you for more information.

Recent employee profiles:

|

|

|

|

|

|

|

TABLE of CONTENTS

|

What’s new on the web |

The Split Rock Bridge in Pipestone County is significant for its high artistic value as an outstanding example of an ornamental park bridge and as the largest stone-arch span of any active highway bridge in Minnesota. Photo by LHB |

Historic bridge website

The historic bridge website has been updated, featuring a fresh look, user-friendly navigation and detailed information on historic bridges in Minnesota.

Each historic bridge now has a dedicated webpage that includes the bridge’s history and significance, key facts, images, document resources and Google map and rehabilitation activities (if applicable).

The site also features several ways to locate historic bridges: you can now search by region using a state map to locate historic bridges, or you can browse all historic bridges by county and by bridge number/name.

The site updates were a joint effort among MnDOT’s Cultural Resources Unit, State Aid for Local Transportation Division and consultants LHB and Mead & Hunt.

New Library Materials

New Library Materials are available at www.mndot.gov/library/newlibmat.html. A new item highlighted in this issue is the 2015 ENR Public Works Contracting Costbook. The Costbook contains accurate and up-to-date material and labor costs for a wide range of public works projects.

New Library Materials is a compilation of titles and other resources added to the library collection during the previous month. If you would like to be added to the distribution list, contact pamela.m.gonzalez@state.mn.us or 651-366-3749.

Previous editions of New Library Materials are archived and available at www.dot.state.mn.us/library/recacq-archive.html. For other information requests, contact the Library at 651-366-3791 or e-mail library.dot@state.mn.us, or send requests via the “Ask a Librarian” web page at www.dot.state.mn.us/library/asklibrarian.html. |

|

|

|

|

TABLE of CONTENTS

|

Asset Management Battle helps improve maintenance data accuracy |

Editor’s note: This is one in a series of articles illustrating the benefits gained from the Enhancing Financial Effectiveness effort, MnDOT’s Wildly Important Goal. Asset Management is one of four Battles, or strategic focus areas, that are leading the EFE charge. The other Battles are Financial Management, Project Management, and Information & Outreach. In addition, there are a number of efforts throughout the agency that don’t fall under these four categories. These projects are called “Other WIG Supporting Activities,” and also contribute to MnDOT’s overall EFE effort.

By Dave Solsrud, Asset Management WIG project lead

From left, Jamie Hukriede, District 3A area maintenance engineer, and Mark Panek, District 6 West operations manager, describe the new timesheet validation report at the subarea maintenance supervisors meeting in Detroit Lakes Sept. 9. Using the Supervisors Pavement Maintenance Validation Report will save MnDOT an estimated $4,000 per pay period during patching season. Photo by Dana Casey, District 4 |

Timesheet coding can be complicated, especially for district maintenance crews.

A field employee, for example, must choose from a dozen Source Types (activity codes) for pavement repair, maybe a hundred road segments in a district, a materials list that includes about a thousand items, and infinite possibilities for highway mile points. He or she needs to enter a unique eight-character Project I.D. for each road segment worked on, as well as any special funding numbers for programs like the dedicated 2014 season patching account.

And pavement repair is just one of the activities and resources that maintenance crews must track.

Field staff are asked to do their entries daily to ensure accuracy. But after a hard day in the sun and the traffic, and when there’s only one computer to share among several field crew employees, staff may find it very difficult to attend to the detail necessary to accomplish this work. And sometimes, the system can be confusing, returning error messages because codes may be incompatible for example. Then frustration can really set in! If employees don’t remain persistent and committed to accurate recording, data quality may suffer.

A supervisor has a high level of responsibility for ensuring that timesheet data recorded is of high quality and accuracy. However, a field operations supervisor typically may have to review the timesheets of 20 to 30 direct reports. Multiply that by the number of days worked in a pay period; the number of project entries per day; the number of labor, equipment, materials (LEM) entries per project; and the number of milepoint fields to approve and you have a huge task.

Let’s say, for example, there are 25 employees x 10 days worked in a pay period x 1.5 projects/day average, x 2 Labor, Equipment, Materials entries, x 3 location fields; that’s 2,250 data points for a single supervisor to evaluate each pay period!

Until now, a supervisor’s means of reviewing entries was generally by looking at individual timesheets within RCA. As a result of the Asset Management WIG, additional recording requirements were placed on employees. The Asset Management Team felt that expecting supervisors to page through such a high volume of information was impractical. Can you imagine trying to do that?

Thanks to the Asset Management Battle and its Pavement Team, a new Crystal report is now available to make it simpler for supervisors to review and correct data.

The Supervisors Pavement Maintenance Validation Report displays the entries in columns so that they can be quickly evaluated for outliers. The entries that each employee made for a given “project,” can be corrected before the data gets into the system permanently. The supervisor can run the report in less than a minute generally, saving time and effort, and improving the quality of timesheet data. The report makes it easier for supervisors to provide feedback to employees and to reduce the need to keep correcting recurring errors.

It’s estimated this tool could save each supervisor one to two hours in reviewing and approving timesheets each pay period. Based on approximately 90 supervisors x 1.5 hours x $30/hour, that translates into a savings to MnDOT of approximately $4,000 each pay period during the patching season.

To date, the new report has generated very positive feedback. In fact, supervisors asked to have the funding string added to the original report version to make it easy to track the charges for the new 2014 dedicated patching program. A subgroup of the Asset Management Battle’s pavement team took on the responsibility to develop this report and worked with users and IT folks to make refinements, get it into production, and distribute the final version to supervisors statewide.

The Asset Management Battle’s Pavement Team is also using this tool so that they get a statewide view of how the data recording is going. Each month, “Validation Meetings” are held where the team reviews samples of recorded data. The meetings initially identified areas of confusion and inconsistency, and have resulted in additional RCA software modifications, business process changes and clarifications, additional training and outreach, as well as feedback to supervisors and employees.

This tool enhances financial effectiveness by improving MnDOT data quality, and building the culture of commitment to good data starting directly at the point of entry and the first point of validation.

Accurate data for maintenance activities is the foundation of many important departmental decisions, including being financially effective in managing our infrastructure. This tool provides initial time and cost savings by supervisors, but equally as importantly provides for improved data that will generate more accurate lifecycle cost information, which is critical to overall department effectiveness in managing our pavement assets.

Learn more:

|

|

|

|

|

TABLE of CONTENTS

|

Working on the railroad |

By Bob Filipczak

Bob Filipczak, Communications, found a new way to get from his home in Kimball (near St. Cloud) to the Central Office in St. Paul. He rode the Northstar Line from Big Lake to Target Field in Minneapolis and then took the Central Line to St. Paul. Photo by David Gonzalez |

I have never used the words productive and commute before.

Last week, however, I decided to try the Northstar Line from Big Lake to Target Field. I then grabbed a connection on the new Central Line over to Central Office. For someone like me, who has seen more than his share of traffic jams over the years, spending the commute on a couple of trains was a revelation in productivity.

The first two things people want to know about your train commute is how much time and how much money, if any, did it save you. In both cases, I feel it was a wash. I live in Kimball, so I still had to drive to Big Lake. That added 40 minutes to the equation for time and gas consumption totals, but here’s an apples to oranges comparison:

Kimball to Central Office = 2 hours + $26 for gas and parking

Big Lake to Central Office = 2 hours + $12 round trip ticket*

But as I stated at the beginning, every commute I’ve ever survived in the Twin Cities has been unproductive, frustrating, exhausting, soul-deadening, etc. Here’s a typical exchange when I would get to work.

Lisa: “How was the traffic this morning, Bob?”

Me: “Not too bad, I only ran into five traffic jams.”

Lisa: “That’s not good.”

Me: “It’s worse when all five of those jams merge into one big traffic jam.”

On this bright autumn morning when I jumped on the Northstar Line, I immediately gravitated to the upper level of the car that advertised free WiFi. It provided a great view, a pretty good connection and a silence that would rival a monastery. All around me my fellow passengers were staring at their smartphones in reverent contemplation. I wondered to myself what the monks at St. Johns were doing this morning.

Ironically, the only person not staring at his phone was reading his Bible.

Before I got to Elk River, I had checked and answered all of my email. Before I got to Fridley, I had checked MnDOT’s Facebook page, our Twitter feed and answered all the questions or concerns from our citizens. The rest of the trip I took notes for this article and worked on my laptop on other MnDOT concerns.

When I hit the Central Line, I switched over to my smartphone because the laptop was a bit clunky for those seats. An iPad probably would have been perfect.

The question is: When did my work day start? Was it when I got in the office and sat down in front of my MnDOT-supplied computer at 9:21? Or did my work day start at 7:21 when I got on that train and started working? That’s a discussion worth having and I’m not sure yet what I would advocate. Productivity is a very complicated matter that involves human behavior, and there’s nothing simple about human behavior.

What I am sure about is that I arrived at work completely caught up and ready to jump on the next assignment. More importantly, I arrived relaxed and calm, and I’ve never before used those words in the same sentence with the word “commute.” |

|

|

| |

|